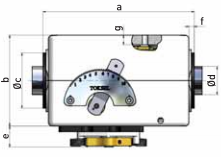

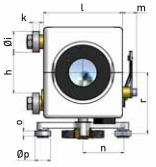

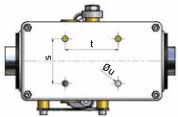

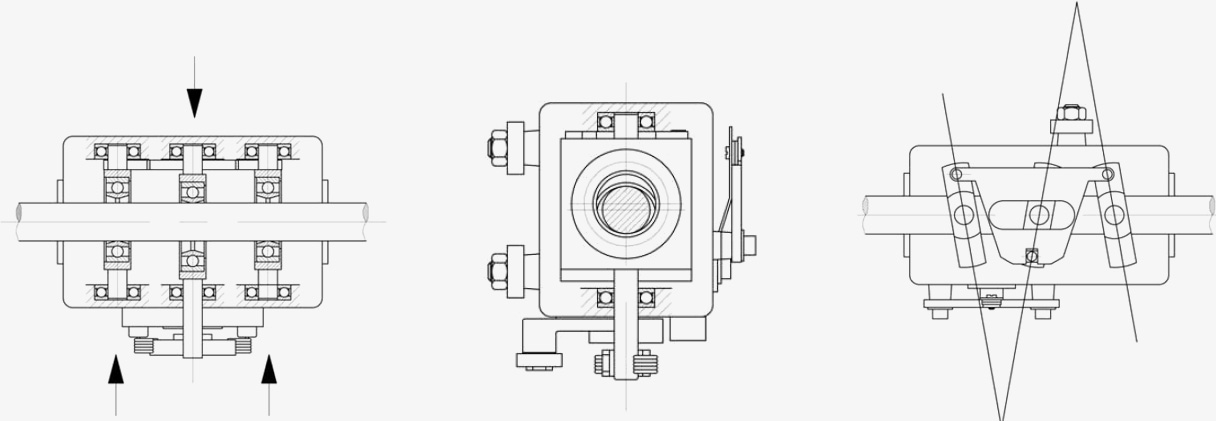

| Models | a | b | Øc | Ød | e | f | g | h | Øi | k | l | m | n | o | Øp | r | s | t | Øu | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

VGØ50 | 269 | 162 | 98 | 50 | 36 | 9 | 17 | 72 | 37 | 12 | 140 | 25 | 65 | 8 | 28 | 101 | 80 | 95 | M12 |

|

VGØ30 | 171 | 114 | 62 | 30 | 33 | 9 | 14.5 | 41 | 26 | 8 | 98 | 21 | 46 | 8 | 26 | 80 | 49 | 80 | M8 |

|

VGØ20 | 142 | 90 | 44 | 20 | 23 | 3 | 12 | 31 | 22 | 7 | 72.5 | 19 | 36 | 7 | 22 | 65 | 39 | 69.5 | M6 |

|

VGØ15 | 99 | 67 | 32 | 15 | 20 | 4 | 7 | 25 | 16 | 5 | 53 | 17 | 26 | 6 | 19 | 51 | 38 | 36 | M5 |

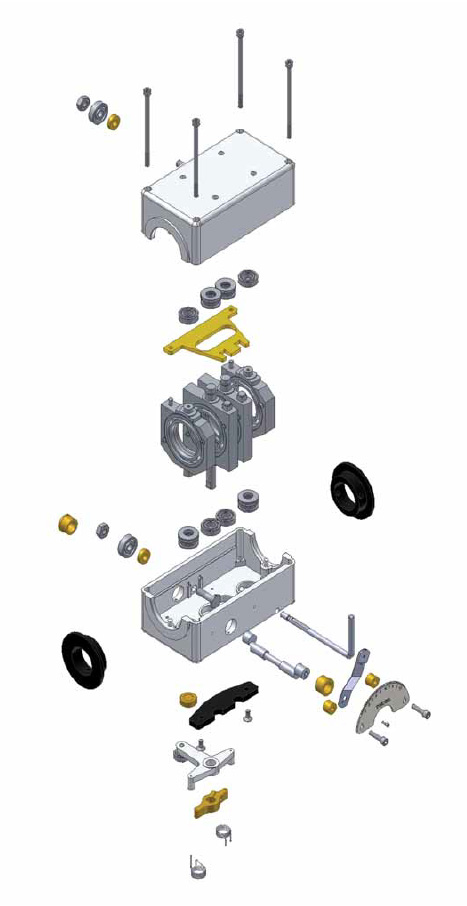

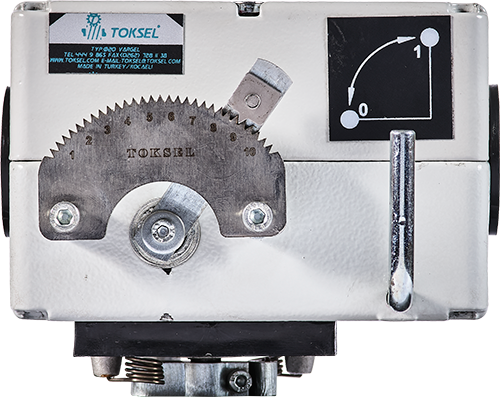

The rotational movement of the straight shaft on which it is working turns into linear movement It takes its power from the rotational movement of the shaft It provides linear motion by pressing at variable angles with special machined bearings such as pitch of nut on shaft. Thanks to the mechanical system that changes the bearing positions on the unit, it moves to the right and lef

Unit can be set in front of roller angle changing with scale speed adjustment can be made.